Following the global energy transition, the consumption of the metals and minerals necessary for the manufacture of wind turbines, photovoltaic panels, batteries and hydrogen production and storage, and other systems is drastically increasing. Moreover, the shift to e-mobility will require batteries, fuel cells and lightweight traction motors not only for cars but also for e-bikes, scooters, and heavy-duty transport. Pressure on resources will further increase due to increasing global population, industrialisation, digitalisation and increasing demand from developing countries: OECD forecasts that global materials demand will more than double from 79 billion tonnes today to 167 billion tonnes in 2060. However, virgin mining – which has considerable, and sometimes irreversible, environmental and socioeconomic consequences – is rapidly becoming unsustainable as primary resources are in increasingly short supply and energy consumption continues to increase.

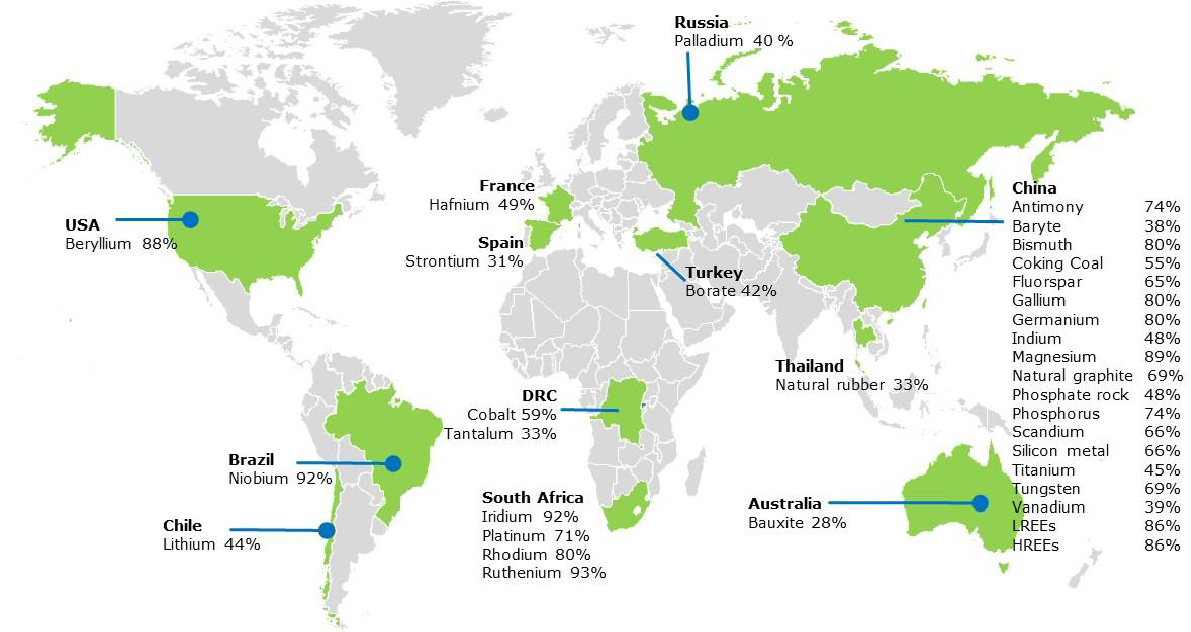

Global competition for resources will become fierce in the coming decade and the dependence of critical raw materials may soon replace today’s dependence on oil

Not by chance, on 16 March, the European Commission published the Critical Raw Materials Act, a legislative proposal intended to strengthen the EU’s autonomy in the supply of key raw materials in the aftermath of Covid-19 and the energy crisis following Russia’s invasion of Ukraine. Indeed, many raw materials needed in the European green and digital industry are imported from abroad as they aren’t available locally or are in limited supply. Photovoltaic panels and wind turbines, for example, can’t be built without tellurium, gallium and neodymium and smartphones contain up to 50 different metals. Several of their components are typically obtained from China, and the demand for these items is increasing as people upgrade to newer models of electronic devices every few years.

The rise of urban mining

At the same time, people are getting rid of electronics just as fast, filling landfills with an increasing amount of e-waste. However, electronics is the source of both hazardous materials and valuable secondary resources: the resources in the landfills sometimes have a higher concentration and thus are more valuable than ores for conventional mining. From this point of view, cities can be seen as urban mines, a sort of open-air reserve of raw materials that can be exploited with the creation of new value. Changing the status of traditional mining to urban mining as the source of materials implies a shift from the exploitation of natural stocks to the exploitation of anthropogenic resources. Strongly inspired by the concepts of industrial metabolism and industrial ecology, urban mining extends the concept beyond the walls of the industry. Urban mining is based on the value recovery of secondary raw materials from anthropogenic sources through biological, chemical, or physical procedures and technological input.

The importance of urban mining as a tool in the application of the circular economy is based on two important foundations: value recovery through the reinsertion of residual materials as inputs in the supply chain and the mitigation of potential environmental and social impacts of waste generation through circularity-based alternatives to disposal. The urban mining approach offers a range of benefits, particularly in ensuring secure and sustainable supply chains. Where natural resources are often concentrated in remote or geopolitically unstable regions, urban mining unlocks these resources close to where they are needed, increasing resource independence and reducing transport costs. Furthermore, increasing recovery and recycling rates reduces the strain on natural resource reserves, extending the length of time they can be used.

The limits of urban mining

There is a gap between the raw material production potential given by urban mining and the amounts of raw materials effectively recovered. From the quantitative point of view, urban mining is currently equivalent to the recycling of end-of-life products. Of course, some electronics are recycled in Europe, but the process is still crude and involves melting devices together in a furnace and focuses on removing the most valuable metals, typically copper, silver and gold. Particularly, the current systems have many limitations for critical raw materials which recovery from landfills and tailings ponds is negligible. For most of these, the recycling rates are less than 10% of the potentially recyclable amount. This follows from the challenges – from organizational to technological to economic – facing the recovery of raw materials from a highly diverse and highly complex resource base distributed worldwide.

Product designers must strike a balance between product efficiency and recyclability: more efficient products are often more complex and difficult to recycle, but the improved efficiency lowers the energy consumption and environmental footprint of the product. At the same time, governments can make a major impact by implementing a regulatory framework that incentivises recycling over landfilling, directs secondary materials to where they are needed most, and provides an infrastructure to support recycling. If the EU can successfully implement the ambitious goals of the Green Deal agenda, urban mining can take its place as an indispensable part of a truly circular and climate-neutral economy.